Using Chain Extenders to Modify Release Rates of Orange Oil from Poly(Urea-Urethane) Microcapsules

DOI:

https://doi.org/10.17344/acsi.2015.1434Keywords:

Microencapsulation, Interfacial polycondensation, Orange oil, Release behaviourAbstract

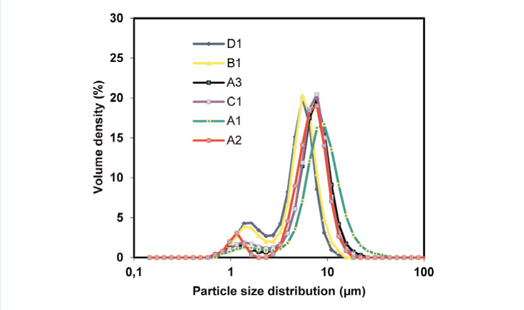

Poly(urea-urethane) and polyurea microcapsules were prepared by an interfacial polymerisation using orange oil as a core material and a mixture of polymeric 4,4-methylenediphenyldiisocyanate and toluene diisocyanate in a molar ratio of 1:0.2 as oil-soluble monomers. The membrane composition, its thickness and other properties were varied by changing the type and amount of oil-soluble monomers and water-soluble chain extenders, such as ethylenediamine and diethylenetriamine based on amine groups and 1,4-butanediol and polyethylene glycol 400 based on hydroxyl groups. Studies of the morphology and release behaviour of microcapsules show high dependency on the reaction conditions and reactants’ properties. The release rate of the orange oil from microcapsules is highest when using a polymeric linear chain extender, polyethylene glycol with a molecular mass of 400. Improved mechanical stability and a slower release rate of microcapsules were achieved by a thicker membrane and by using the branched multi-functional chain extender diethylenetriamine.

Downloads

Additional Files

Published

17.07.2015

Issue

Section

Applied chemistry

License

Except where otherwise noted, articles in this journal are published under the Creative Commons Attribution 4.0 International License