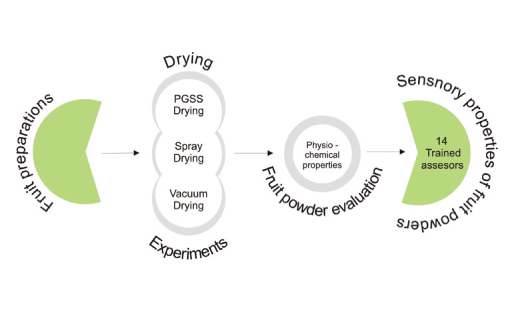

Effect of drying parameters on physiochemical and sensory properties of fruit powders processed by PGSS-, Vacuum- and Spray-drying

DOI:

https://doi.org/10.17344/acsi.2014.969Keywords:

PGSS-drying, Vacuum-drying, Spray-drying, Sensory evaluationAbstract

Aim of this experimental work was to investigate the possibility of producing fruit powders without employing drying aid and to investigate the effect of drying parameters (e.g., process temperature and pressure) on the final powder characteristics such as retention of colour, flavour and antioxidant activity. Raw fruit materials (banana puree, strawberry puree and blueberry concentrate) were processed using three different drying techniques operating under sub-atmospheric (freeze-drying), atmospheric (spray-drying) and high-pressure (PGSS-drying) conditions. The results obtained from the experimental work indicate that investigated fruit powders without or with minimal addition of maltodextrin can be produced. Additionally, it was observed that an increase in process temperature results in a higher loss of colour, antioxidant activity and intensity of the flavour profile.

Downloads

Additional Files

Published

Issue

Section

License

Except where otherwise noted, articles in this journal are published under the Creative Commons Attribution 4.0 International License