Camel Bones as a Source of Fat: Optimization of Extraction Methods and Fatty Acid Composition Analysis

DOI:

https://doi.org/10.17344/acsi.2024.9089Abstract

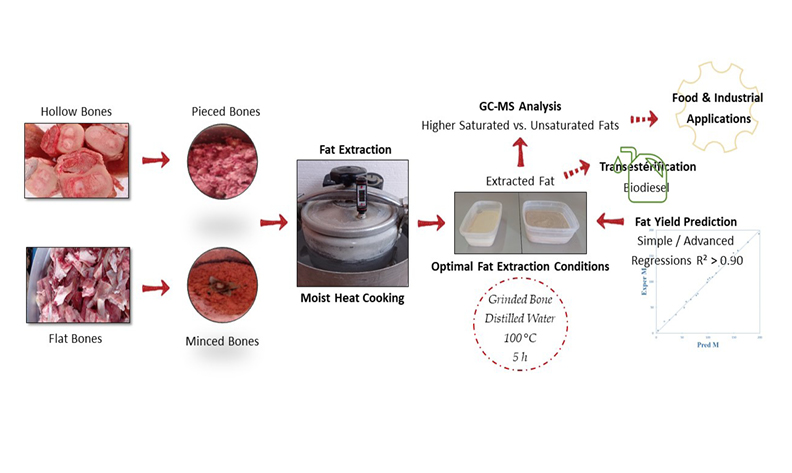

This study explores the viability of using camel bones, an abundant by-product in North Africa and the Middle East, as a novel source of fat for biodiesel production. A moist-heat extraction process using a pressure cooker was employed to extract fat from both hollow and flat bones. The initial phase of the study optimized temperature (40-100 °C) and duration (0.5–5 hours) using ordinary water, confirming that fat yield increased with both parameters. A subsequent phase significantly enhanced extraction efficiency by introducing two key optimizations: grinding the bones to increase surface area and using distilled water to eliminate ionic interference. This approach achieved a peak yield of 26.69% (by bone mass) for hollow bones at 100 °C after 6 hours. Compositional analysis indicated a predominance of saturated fatty acids. The findings confirm that camel bones are a promising fat source for industrial applications, such as biodiesel production via transesterification, with an optimal extraction window of 3 to 5 hours identified for an efficient process.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Mohamed Mokadem, Habib Farhat, Khadra Mokadem

This work is licensed under a Creative Commons Attribution 4.0 International License.

Except where otherwise noted, articles in this journal are published under the Creative Commons Attribution 4.0 International License