Optimization of The Bleaching Process of Sunflower Oil

DOI:

https://doi.org/10.17344/acsi.2024.8816Abstract

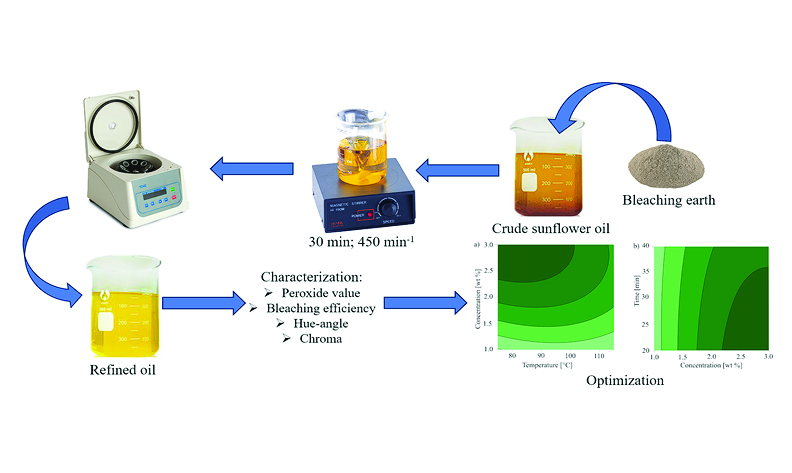

Bleaching is a crucial step in oil refining that removes unwanted pigments and oxidative products, which degrade oil quality. This study evaluated the effects of temperature (75–115 °C), adsorbent concentration (1–3 wt%), and time (20–40 minutes) on sunflower oil bleaching using a Box-Behnken factorial design in Minitab 21. Responses were divided into two groups: (I) peroxide value and spectroradiometric-based chroma and hue-angle, and (II) peroxide value and spectrophotometric-based bleaching efficiency. Under optimal conditions (approximately 78 °C, 2.95 wt% adsorbent, and 20 minutes), peroxide value decreased from 1.8 meq/kg to 0.398 meq/kg, chroma reduced from 45.89 to 9.61, hue-angle increased from 92.69 to 105.55, and bleaching efficiency reached 71.86%. Composite desirability was higher in the first group (0.97 vs 0.89), primarily due to the more objective nature of spectroradiometric parameters (hue-angle and chroma).

Keywords: Oil bleaching, Optimisation, Response Surface Method, Sunflower oil

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Nebojša Vasiljević, Suzana Yusup, Vladan Mićić, Goran Tadić, Dragica Lazić, Duško Kostić

This work is licensed under a Creative Commons Attribution 4.0 International License.

Except where otherwise noted, articles in this journal are published under the Creative Commons Attribution 4.0 International License